-

Sewing Patterns

-

Fabric

- Sewing Supplies

- About

- Blog

- Gallery

-

June 18, 2022 2 Comments

In 1851, the first attempt at a zipper was patent and named the "Automatic Continuous Clothing Closure." This device would take on different reiterations, a Worlds' Fair, and finally a 1930's children's clothing sales campaign to introduce the zipper as we know it. Adding zippers to children's clothing promoted self-reliance making it possible for little hands to dress themselves. In essence, the zipper helped to revolutionize wearing clothes for the young and old alike. Hence, our self-reliance, security, and convenience still somewhat depend on that interesting piece of tape with teeth. Besides, few things when used make the delightful sound in which they were named. Zip!

It is easy to take a zipper for granted until it no longer works, relegating a "broken" garment to the "to mend" box or worse. There is no need to shy away from this simple to use, yet ingeniously engineered device. In this blog you will see how to add a zipper to your sewing and hopefully help replacing one less daunting.

While there are different types of zippers meant for varying applications this blog will concentrate on adding the commonly used invisible zipper to a center seam. In Part One of this blog, the Folkwear 220 Garden Party Dress was adjusted, so it's authentic buttons and placket could swapped out for a zipper. Keep reading to learn how the 220 Garden Party Dress will get a zip up the back.

The key to a successful and stress-free zipper installation is in part about orientation. In this blog you will learn a few simple steps and tips to make installing a zipper easy!

Getting StartedYou will need an invisible zipper at least 24” (61cm) long (depending on your back length), fusible interfacing, thread, and a zipper foot for your sewing machine. Either an invisible zipper foot or a standard zipper foot will work. I will be using both types of zipper feet in this blog.

If you are not familiar with using an invisible zipper foot, give one a try, because they make installing zippers a breeze.

Zippers

They come in varying lengths, colors, and coil or teeth sizes. The coils/teeth are made of either metal or plastic. The tape is typically made of polyester, nylon, or cotton. You can purchase zippers in predetermined standard lengths or have a zipper cut to the length you determine.

Tip: If you use a custom-cut zipper, a thread bar-tack will need to be added to the end of the zipper tape to keep the slider hardware from slipping off.

A regular zipper with visible teeth (made of metal or plastic) can also be used, but if you prefer a less obvious zipper, then an invisible zipper is best.

Prepare to Add the Zipper

Invisible zippers close with interlocking coils or teeth made of plastic. Because zippers remain zipped-up until they are ready to be used the teeth tend to be tightly curled and need to be opened up to make stitching easier. Use your fingers to uncurl the teeth while pressing the coils/teeth flat with the tip of the iron. Be sure to turn down the heat (synthetic setting) on your iron to avoid melting the plastic coil/teeth. The coils should retract back a little bit. Do not try to press the coils so they remain perfectly or permanently flat.

Be sure the waistband, or any seams, a zipper will be added to are neatly pressed before adding the zipper.

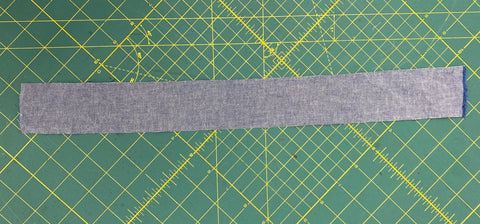

Zippers take a lot of use; therefore it is a good idea to add a lightweight fusible interfacing (according to manufactures instructions) to reinforce each side of the zipper tape and the seams. Add the interfacing to the wrong side of dress center back, aligning the tape to the top and side edges of the fabric. I like to cut the interfacing 1" wide (if using a standard 3/4" width zipper) and cut the interfacing length equal to the zipper.

Be sure to fold and pin the waistband facing out of the way before adding the interfacing and for stitching the zipper to come.

Properly Orient the Zipper to the Fabric.

You may find it useful to orient yourself the same way every time for this process. I try to be consistent and start working with the right side (as you wear it) of any garment project. All the directions and photos that follow, use this orientation. But it does not matter which side you start with. The important part is to take your time and get the orientation correct.

Start with the right side of the dress/garment facing up.

Take note that the zipper has a right and a wrong side. Inspect the construction of the zipper and the right and wrong side will become evident to you. I find looking at the slider hardware to be the quickest way of determining the sides.

Place the wrong side of the zipper facing up, with the zipper open to the dress. Check that the right side of the zipper is to right side of the fabric.

Next, be sure the coils face away from the center back edge and towards the dress. The edge of the zipper tape should be positioned, running parallel to the center back edge of the dress.

Orient the zipper to the center back of the dress as seen below with the zipper completely open.

Use a seam guide, measuring tape, or ruler to make sure the zipper coils/teeth line up with the seam allowance. Align the coil/teeth at the 1/2" (6mm) seam allowance (1/2" from the center back edge), as seen in the photo below. Always use the seam allowance indicated on a pattern (in this case, it's 1/2").

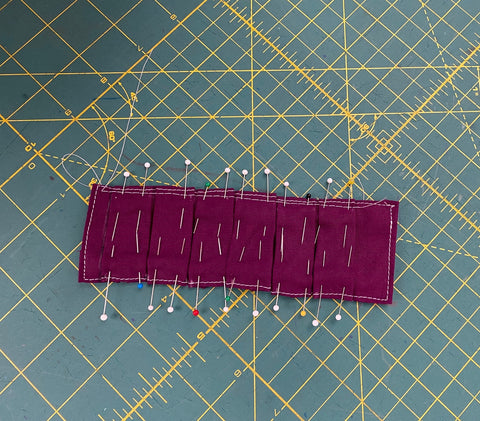

Measure and pin the zipper tape to the fabric with the pins inserted parallel to the zipper. This will allow for easy pin removal when stitching. Check again to be sure the alignment is correct down the entire zipper tape and be sure the tape is not accidentally twisted.

Stitching with an Invisible Zipper Foot

Align the left groove of the zipper foot over the coil/teeth. With your fingers move the coils/teeth so it stands upright and fits in the groove of the zipper foot before beginning to stitch.

Use a medium length stitch. Avoid a stitch that is too tight (short) or too loose (long). Use Polyester thread because it is less likely to break.

Begin the stitching with a back stitch to secure the top of the zipper tape. Take your time and slowly stitch (to help prevent fabric from puckering) the full length of the zipper, removing the pins one at a time, before they reach the foot. Stop when you reach the slider hardware. make a back stitch about 1/2" (13cm) long. You will be unable to stitch any further, because the slider hardware will be in the way.

Notice the close-up view below, of how close stitching is made next to coils. The nice thing about an invisible zipper foot, is that the groove ensures the stitches are made at the correct distance from coil.

If using a regular zipper foot be sure to not stitch too close the coil/teeth. If the stitches are too close, the zipper will not open and close properly. If the stitching is made too far away from the coil/teeth, the zipper will show and not be held securely to the fabric.

Once one side of the zipper tape is sewn in place, go ahead and test the zipper by closing it. It should open and close easily and smoothly. If not, access the problem, unpick the stitching, and try again if needed.

This is also a good time to mark on the free zipper side where it will align with the waistband. This will keep the zipper from getting out of alignment when attaching the other side of the zipper to the dress. If you have a waistband, as this dress, does, mark on the zipper tape where it should meet the waistband so the right and left sides of the dress match up.

Unzip and add the opposite side of the zipper to the opposite side of the dress edge.

For the opposite side, pin the zipper (unzipped) to the fabric, making sure the right side of the dress is facing up. The wrong side of the zipper should still face up. Check that the right side of the zipper is to right side of the fabric.

If you started with the right side of the dress (as you wear it), then this is what your orientation should look like. (See photo below).

Remember the coils/teeth should be facing towards the dress and the edge of the zipper tape should be parallel to the center back edge.

Position the tape from the top edge of the fabric as before. Align the zipper at the waistband as marked.

Measure so that coils fall on the seam allowance as before.

It is easily for the zipper to get twisted, so check to be sure the zipper tape is laying flat.

Use the opposite groove of the invisible zipper foot to stitch this time. If you are following along, then the right groove is used.

Begin and end the stitching as before.

Test the Zipper

Now that the zipper is installed, zip it up and down to test that is closes easily and smoothly.

Give the zipped-up, right side of the dress a gentle press before continuing.

Stitch the Remaining Skirt Seam

With the back of the zipper still closed, lift the zipper tape out of the way. Sandwich the zipper in the seam allowances and pin the seam allowance down the remaining length of the skirt seam.

Switch the invisible zipper foot out for a more narrow standard zipper foot. Position the foot as close as you can to the left of the zipper. Start 1/2" (6mm) to 1" (2.5cm) above the end of the zipper stitching. Slowly stitch forward and then make a small back stitch.

The zipper causes bulk in this spot, making beginning the new stitch line on top of the zipper stitch line difficult, if not impossible. Do not try to force positioning the needle on top of or right next to the sandwiched zipper. Just get as close as you can. (See the photo below). This small amount of space is generally not enough to prevent the zipper and seam from looking nice once finished.

With the seam allowances matched and pinned, stitch down the remaining length of the skirt seam and end with a back stitch.

Press the seam open below the zipper.

Lift the zipper tape tail and press the seam with the tip of the iron. This area can pucker, so go gently.

With the right side of the dress back facing up, press the zipper seam lightly to create a smooth finish.

Finish the Waistband Facing

With the zipper successfully installed it is time to finish the interior waistband facing. Begin working with the wrong side of the dress back facing up, and with the wrong side of the waistband facing, facing up and laying flat. The long bottom edge of the waistband facing (top when open as seen below) should be turned under 1/2" (6mm).

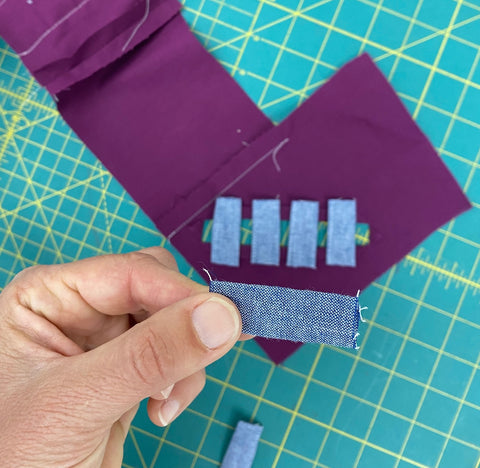

Fold under and pin the short ends of the waistband facings on either side of the zipper. Be sure that the zipper slider hardware can easily move past the folded under edges. If the edges are too close to the zipper slider, the fabric may get caught. Press the edges.

Fold the down each of the waistband facings and align the long turned under edge of the facing using the parallel skirt stitching line as a guide. Pin the facing in place for a clean finished look.

Hand whip-stitch the the turned under short edges of the waistband facing to the zipper tape. Hand whip-stitch the turned under long edge to the skirt, using the stitch line as a guide.

I hope this blog has helped ease any zipper installation apprehension you may have had. It is easy to add an invisible zipper to clothing or so many other projects. Once you have tried installing a zipper a time or two, hopefully you will not hesitate to expand your sewing repertoire. Don't be surprised if you never look at a center seam the same way again.

June 17, 2022 1 Comment

The buttoned back of 220 Garden Party Dress is part of the charm (and authenticity) of this historic dress. It is a bit unusual in current dresses and can be a feature that is fun and interesting. However, it is not always practical. It can be hard to reach buttons in the back, and hard to manage buttoning them backwards. It certainly would be helpful to have a maid to help us when putting on this dress (as might have been the case when it was worn in the early 1900s), but since that is extremely unlikely, another option is to replace the button placket with a zipper.

It is always nice to have the option of a zip-up back closure when it comes to making dresses because they are fairly easy to use and insert. The Folkwear 220 Garden Party Dress back button closure and placket can easily be replaced with a zipper. This can be done to either the contemporary (View A) or traditional (View B) versions offered in the pattern. In Part One of this blog you will learn how to make a minor pattern adjustment, that will allow you to trade out button/buttonhole closure and the placket for a long invisible zipper. This technique will work on any dress or blouse that has a center back seam.

Keep reading to learn how this technique will enable you to add a button and placket closure or a zipper to the back of any center back seam, by simply adding or subtracting fabric.

In Part Two of this blog, you will learn a tried and true method for adding an invisible zipper to the Garden Party Dress and how to neatly finish the interior waistband facing.

The focus of this blog is to make an adjustment to the center back of the dress so a zipper can be added later. For the purposes of this blog I will not be making the entire dress. Instead, I am making a muslin of the dress back only for view A. You can make the adjustment as you construct the final dress if you like. However, be sure to read ahead so you are confident in what to do.

Pattern changes to be aware of:

If you want to try the adjustment along with me, grab some muslin or scrap fabric and cut out the Bodice Back B, Waistband/Waistband Facing F, and Skirt Back H pattern pieces as instructed.

Adjust the Back Bodice

In order to replace the button closure with a zipper on the back bodice, you need to determine how much overlap or turned under self-facing has been built into the pattern. This extra turned under fabric was originally built into each side of the back bodice pattern pieces to accommodate the buttons on one side and the buttonholes on the other side. In this case 1-1/2" (3.8cm) was added to the center back of each bodice piece.

All that is needed to accommodate the zipper is a seam allowance. Simply trim away the extra 1” ( 2.5cm), leaving a 1/2” (6mm) seam allowance at the Center Back or center back line of each back bodice pieces. See the illustration below.

Note: The Waistband/Waistband Facing and Skirt pieces do not need adjusting and are ready to use as is. Also, the flanges are not being used in making this muslin, because they are only decorative and do not effect the construction.

Add Waistband/Waistband Facing to Back Bodice

With right sides together, pin and stitch the Waistband to the Back Bodice, drawing up the gathers to fit, matching notch 6. The waistband edge should be even with the center back edge of the bodice.

Notice the red tip pin marks notch 6.

View of the wrong side with gathers drawn at center back edge to notch 6.

Pin the right side of the Waistband Facing to the wrong side of the bodice, matching notch 6. Be sure to not catch the Waistband in the pinning or stitching. Stitch in place using the previous stitching as a guide. End the stitching approximately 1" (13mm) from the center back edge. Fold back the un-stitched section of the waistband facing and pin to hold it out of the way in order to add the zipper later.

Add Skirt to Waistband

Remember to not stitch the skirt backs together as the instructions direct.

Make two rows of gathering stitches within the seam allowances at the top of the skirt edge. With right sides together drawn up the skirt to fit the waistband, pin, distributing the gathers evenly. Then, sew being careful not to catch the waistband facing in the stitching. Press the seam towards the waistband.

If you unpinned the un-stitched section of the waistband facing, like I did, to make construction easier, be sure to pin it back out of the way again before adding the zipper.

Repeat for the opposite back side to the dress.

You should now have a right and left dress back, consisting of the bodice, waistband/waistband facing, and skirt. The two separate backs will become one piece when the zipper is added.

In the Part Two of this blog you will learn a tried-and-true method for installing an invisible zipper to the back of the Folkwear 220 Garden Party Dress. And learn how easy it is to create a clean finish to the waistband facing.

If you have not already done so, take advantage of the sale price for the Folkwear 220 Garden Party Dress during the month of June and join in to learn how to zip it up the back!

June 11, 2022 2 Comments

by Victoria Watkins

I believe most of us who have any amount of interest in fashion has had the experience in which we have complimented someone's dress only to be told with enthusiasm, "Thanks! It has pockets!" Or, maybe you've said that to someone who complimented your dress! Today, I'll show you how I added pockets to our 142 Old Mexico Dress pattern, and give you ideas on how you can do the same. Plus, we are offering you a free template for an in seam pocket so you can add them to any garment that needs a pocket!

The 142 Old Mexico Dress is probably our most popular pattern. It is a breeze to sew, makes a dress or a shirt, and has lots of options for fabric or to add embroidery. I choose an orange organic poplin we had in stock at Folkwear to make this dress. I may add embroidery to it later (stay tuned for an embroidery color theory blog post!). Usually you would embroider before constructing the dress, but it is fine to add later as well - you can do whatever suits your fancy.

For this dress, the body assembly includes a yoke, a front, and a back. I could have chosen to just roughly measure to where I'd like the pocket pieces to sit and put them in in the first step, but instead I chose to construct the dress up until the side seams are to be stitched (yoke is finished). That way I could try on the mostly-sewn dress and physically determine where the pockets would fit best.

On the front and back pieces of the pattern, there is a dot near the underarm that designates where to stop stitching along the side seams - and where the lower part of the sleeve is inserted. Coincidentally, when trying on the dress to determine where the pocket would go, I noticed that my ideal spot for the pocket was slightly below that dot. In order to close the side seam and prevent the top of the pocket from flapping open with the sleeve pieces, it's necessary to have some amount of seam above the pocket. For my height, I chose to measure down 1.5 inches from that dot to mark the place where the top of the pocket piece would rest.

Next, I created the pocket pieces. Both sets of pockets (one on each side) need two pieces, so 4 needed to be cut out. This pocket piece has been used in several Folkwear patterns (and will be in a new pattern coming out next month!). You can download this pocket piece here. It prints on legal-sized paper (or A4 paper), or you can print on two sheets and piece together. This pattern piece includes markings for notches as well as alignment dots and stars. Line up the top dot on the pocket with the top of where you want your pocket opening to be.

The above photo shows the general placement of the pocket in reference to the yoke. To sew the pocket to the dress, I placed right sides together and raw edges matching, as you can see below.

I sewed the pockets to each side seam between the pocket dots, right sides together. Remember that these are sewn on before stitching the side seams. Then, I pressed the pocket pieces "out", away from the body of the dress.

With the pocket pieces pressed away from the dress body, you can then place front and back dress pieces together and align the right sides of the dress and automatically have the pocket with right sides together as well. The above photo shows the dots from both the original 142 Old Mexico Dress pattern, as well as the alignment dot I added for the pocket and the star marking on the pocket. These will be your reference for the following steps.

I sewed from the bottom mark (which is a box on the 142 tissue) up to the point where the star mark is on the pocket piece. Next, I sewed between the top dot on the dress and the dot marking the top of my pocket opening.

Before sewing the pocket bag pieces together, I chose to serge the side seams entirely to finish the raw edges. You can finish all edges how you like, but it's easier to do this now before the next step, which creates a segment of side seam that is difficult to access for seam finishing.

I sewed around the outside edge of the pocket bag (from the top dot on the pocket piece to the bottom dot), making sure to sew into the stitching of the side seam at the start and finish. I pressed the entire side seam and pocket toward the front of the dress, and then pinked the raw edges of the pocket to finish. Of course, you can use whichever finish you like on the pocket bag.

From there, I continued the dress as instructed in the pattern. I hope this guide inspires you to try adding pockets to your 142 Old Mexico Dress pattern, or any other dress with side seams that you're sewing!

May 31, 2022 24 Comments

by Molly Hamilton

You may have heard from other small, independent pattern companies (and I may have mentioned it before), but we are changing up how our sewing patterns are printed. We are transitioning our pattern printing away from the way our patterns have been printed for decades. While this behind-the-scenes decision making in our company could remain behind-the-scenes, I thought you might like to know why some of our patterns are out of print, just available as PDF, or why the prices are going up. This story isn’t only about supply chain issues, although they do affect us - pricing, gas/transportation, and paper shortages hit all industries. This story is about how and why our patterns are available in different formats and why it is my goal to have nearly all, if not all, our patterns available as paper patterns, while also digitizing our patterns so they can be available as PDF patterns and be preserved for the future.

For many years we have printed our pattern tissues, instructions, and covers at McCalls printing facility in Kansas. McCalls printing (and the associated pattern company) was bought by a large multinational corporation several years ago. They changed their business strategies. This past fall they shut down the Kansas plant and transitioned to a plant near Chicago, eliminating the only printer in the country who could print on wide format tissue. This printer served most smaller independent sewing pattern companies like ours. With the new plant, our pattern minimums increased by double and the only tissue option was a lighter tissue than we normally print on. We have printed on 12# white tissue for the last 5 years and the new option would only be 8# brown. The much higher minimum order would also mean that it would not make sense to continue to print our patterns that sell more slowly. If I ordered 1000 of a slow-selling pattern, it could take 20 years to sell them at their typical rate. That means 5+ years to break even on the investment, and we have to store the patterns and pay for the place to store them. It does not make economic sense for a small business like ours. The seemingly best business option is to only do PDF patterns, especially for these slower-selling patterns.

With all of these factors, it may not seem to make economic sense to have nearly all of our patterns available as paper patterns, but that is my goal. First, there is a demand for paper patterns. But for me, this is also an accessibility issue. Patterns only available as PDFs become less accessible to customers who don't have reliable internet access or don't have a computer and/or printer (or a print shop nearby). This is especially important for many of our folk patterns which we know are purchased for special occasion outfits. For example, I have seen this with our 120 Navajo Blouse pattern. It is a slow-selling pattern, and often (probably mainly) used by Navajo women to make clothes to wear for important occasions. We know from conversations with these women, and from our orders, that the print pattern is an important option for these customers. Having our patterns available as PDFs may give instant access to people internationally (and more tech-savvy customers), but paper patterns also provide accessibility in other ways.

Moving Forward

Before the McCalls plant shut down, I got as many patterns printed as I could. We do have some patterns with the lighter, brown tissue, and they are priced accordingly (see the 503 Poiret Cocoon Coat). Over the last 6 months I have explored options for printing so that we can have flexibility and the paper options we want going forward.

This is complex. Some of our pattern pieces are quite large and don't fit on most available wide-format printers. Many printers will not use paper less than 20#, which is quite heavy and expensive for larger print runs. After many conversations and much research, we have found some options that work.

We are currently working with two printers who can print at reasonable prices. They print on a bond paper, which is not the tissue we prefer, but still lightweight enough (and is more durable than tissue). As we have sized patterns up, we also have to use more paper to print the patterns, which also affects the price of the pattern. In some cases, very large pattern pieces won't fit on the paper available to print. We have to "tile" the pattern and you will need to place the pattern tissues next to each other to get the full pattern. For the largest pattern pieces, the price is higher because the printers need to charge more to meet their bottom line. This means some of our pattern prices will need to go up to afford the printing; but most will remain close in price to what we have currently. Because these printers do not have minimums we can print the number of patterns we need, which does save us some overhead costs and makes it convenient to make pattern changes or even to offer new patterns. We are using a local print shop for all our instructions and covers now, and we are assembling patterns in-house. The paper size for our instructions decreased a little, but it is not terribly noticeable. The local company does a great job and we are very pleased to work with them.

This is all to say that the printing process can be complicated and there are a lot of moving pieces - and we have a lot of patterns to print! Ultimately, we may also have to decide which patterns to keep in print, depending on how well they sell, the printing minimums for that pattern, the importance of accessibility, and the cost. These decisions will be hard as every pattern in our collection has fans who love it dearly.

If you have read to the end, I hope you have enjoyed a bit of information about how, and why, our patterns are available the way they are. As I mentioned before, it is my goal to have nearly all of our patterns available as paper patterns and PDFs. The road to doing so is sometimes tricky.

Please let us know if you have any questions about our pattern printing or what we are doing. And, as always, we deeply appreciate your interest in, and support of, Folkwear over the many years!

May 25, 2022

by Molly Hamilton

The 121 Guatemalan Gabacha has several authentic detailing options that can be used to decorate the yoke of this very cute dress (or apron). These techniques were used on the original dress samples Folkwear had, and were clever and simple enough that they were included in the pattern. So you can see the instructions for how to make these fun designs in the newly re-released (and re-sized, up to 54" bust) 121 Guatemalan Gabacha, but I am also going to show you how to do them here. You can also think about how these techniques could be used to decorate other sewing projects you have - blouses, shorts, table cloths, etc.

Trim

Trim plays an important part in finishing the handwork on the yokes of this dress. At least one yard of trim, such as ribbon, rick rack, or braid, is needed to cover the edges of the handwork. Trim can also be applied almost anywhere on the dress or apron. Six to eight yards would be enough to go around the neck and outer edges of the yoke, the pockets, and the top of the ruffle.

When choosing trim, consider contrasting colors or a matching trim to get the effect you wish. There is a lot of fun and creativity in adding decorations to the garment you are making. Let your imagination go wild!

Decorative Technique #1

This is the simpler of the two techniques. You will apply it to the yoke only. This technique should be applied after the yoke and yoke facing have been sewn together and before it is sewn to the dress. You will need about 1/8 yard (11.5cm) of extra fabric for this technique, and a little more if you cut the fabric on the bias.

First cut two strips of fabric 15.75" (40cm) by 3" (7.5cm) and press under 1/2" (13mm) on all four edges of each strip. Topstitch to secure.

Make six 3/4" (2cm) full box pleats leaving 3/8" (1cm) on the right side and 1" (2.5cm) on the left side of one strip. To make the box pleats, mark off 3/8" and 1" at each end. Then mark every 3/4" (2cm) starting from 3/8" side of the strip. These marks will serve as a guide to make the box pleats. Be very accurate in order to keep the pleats even. I used chalk to mark on this fabric because the marks can be easily erased by rubbing, but I marked the end sections with an ultra washable marker (Crayola). Pin the pleats in place and press. Staystitch within the seam line.

Pin the pleated strip to the Front Yoke centering it between the sides of the Yoke and with the 1" (2.5cm) end flush with the seamline at bottom of Yoke. Topstitch the pleated strip to the Yoke (but not the yoke facing), close to the edges.

Now you can apply contrasting (or matching) trim around both sides and top of the pleats. Experiment to see what you like! Then, stitch the trim in place.

I'm just showing you what trim could look like, but I did not add any to this sample.

For the next step, use contrasting (or matching) strong embroidery thread and catch both edges of the first pleat in the center. I like to use 2 or 3 strands of DMC embroidery floss. Make three or four overcast stitches, pulling up the edges to meet, forming a tiny bow. Repeat for the remaining five pleats.

Repeat for the other strip and other side of the Yoke, and you are done! The yoke facing will cover all the interior stitch lines.

Video for this decorative technique #1:

Decorative Technique #2

This technique is a little more involved, but gives a really fun look to the dress or apron. It is perfect for using on a sleeveless summer version. You will also apply this technique after the yoke and yoke facing are sewn together but before the yoke is sewn to the dress. You will need about an 1/8 yard (11.5cm) of fabric for the bows, as well as an additional 1/4" yard (23cm) for the optional pleated ruffle.

Use the guide on the pattern tissue and transfer the markings for the diagonal slash lines to the Yokes. Draw a line between the triangle points to create a slash line and cut along the line to the triangles and then to each corner of the rectangle (along the triangle legs). Do this on the yoke and yoke facings.

Press the seams to the inside of the box, creating an opening that is 3/4" (2cm) wide. The length will vary by the size you are making.

Now, cut a strip of fabric that is 2" (5cm) wide by 17½”/44cm long for XS-SM, 21”/54cm long for MD-LG, or 24½”/62cm long for XL-3XL. The length is not terribly important and you can make the strip longer if you want to have more small strips to use in the next steps. You can use the same fabric that you use for the dress or a contrasting or coordinating fabric. Use your imagination! Press under ¼”/6mm on the two long edges. Then press in half lengthwise and topstitch close to the two pressed edges.

Cut this strip of fabric into equal pieces that are about 1.75" (4.5cm) long. You should have about 10 pieces for XS-SM, 12 pieces for MD-LG, and 14 pieces for XL-3XL.

Pin half the pieces across the 3/4" (2cm) opening on the wrong side of one side of the yoke facing, spacing them evenly. You can choose to put as many or as few small strips as you wish here. Topstitch the strips in place 1/8" (3mm) from pressed edge of opening. Repeat for the other side of the yoke facing. Note: I am not using a yoke facing in this tutorial, just one side of the yoke for an example. The technique is the same, but you will be applying this treatment to the yoke facing after the yoke and yoke facing are sewn together.

Also note that you could press these strips so that the seam line is not at the bottom (as above), but is press in the center of the strips so it is not seen from the front.

Fold the front yoke over the front yoke facing, sandwiching the inserted pieces between the yoke and facing. Line up the edges of yoke and facing and topstitch around opening close to the pressed edges. Again, I don't have the yoke for this step in the tutorial.

Using a contrasting (or matching) embroidery thread, make 4 or 5 overhand stitches in the center of both edges of each small inserted strip, pulling up edges to meet, to form a tiny bow - similarly to making the bows in decorative technique #1 above.

You can stop here and add trim around the edges as in Technique #1 (and as I did), or you can keep going with instructions in the pattern for adding a pleated ruffle that I will leave below. If you are going to add the pleated ruffle, don't add the trim until the ruffle is attached.

Pleated Ruffle (optional): I don't show how to make the pleated ruffle in this tutorial, but if you want to add it, cut four strips of fabric 2" (5cm) wide by 12" (30.5cm) for XS-SM, 15" (38cm) for MD-LG, and 19.5" (50cm) for XL-3XL. With right sides of one strip together, fold in half lengthwise and stitch the short ends together with 1/4" (6mm) seam. Turn and press.

Make 1/4" (6mm) pleats across the length of the strip, or as wide as needed to have evenly spaced pleats to fit the length of the opening. Place the ruffle along the length of the opening, and pin in place with raw edge of ruffle approximately 1/8" (3mm) from edge of opening. Topstitch close to the raw edge.

Apply trim (ribbon, rickrack, lace, etc.) flush with all edges of opening and covering the raw edges of the ruffle and the stitching lines.

---------------------------------------------------------------

So, I hope you will try one of these decorative techniques. They are really quite easy to do and are fun to add to your 121 Guatemalan Gabacha dress or apron. Let us know what you make, if you try one of these, and what you think!

May 21, 2022

We have had some questions lately about patterns that are good for pregnancy and nursing. And, honestly, Folkwear (founded by 3 women) has often incorporated designs for these functions of life into their patterns. And traditional folk clothing was also often, by default, designed to be able to be worn on pregnant bodies and/or provide access for nursing. I am listing some of our patterns below that can be good for pregnant and nursing folks. If you have more to add, please add in the comments!

Also, just to be clear, we believe that it should be a woman's choice to be pregnant (and to choose if to nurse, if possible).

102 French Cheesemaker's Smock - a roomy shirt with lots of ease and quite a bit of length; can definitely accommodate growing bellies and breasts. Also can be used as a nursing top. (PDF version here)

107 Afghan Nomad Dress: I know this dress has often been made as maternity wear by women over the last 40 years. The skirt attaches to a very short bodice (not bodice is somewhat fitted but very comfortable) and there is plenty of room for a baby bump. (PDF version here)

111 Nepali Blouse: This wrap blouse has several ties to provide easy access for nursing while maintaining coverage. It is popular as a nursing top.

113 Japanese Kimono: This pattern is classic for a comfortable robe to wear when pregnant or nursing. Great for resting post-partum. Also see 106 Turkish Coat (which is quilted, so is warmer) and 112 Japanese Field Clothing for roomy and adjustable coat/jackets. 113 Japanese Kimono PDF version, 106 Turkish Coat PDF version, 112 Japanese Field Clothing PDF version.

117 Croatian Shirt: Another roomy and long shirt with lots of ease. (117 Croatian Shirt PDF version)

119 Sarouelles: These comfortable and roomy (particularly the African and Turkish) pants are great for those last months of pregnancy when nothing seems to fit. These have plenty of room and are easily adjustable at the waist (made with ties instead of elastic, so you can make them just about any size you need). 119 Sarouelles PDF pattern.

121 Guatemalan Gabacha: This cute dress has plenty of room in the belly area and would work for early pregnancy months. (121 Guatemalan Gabacha PDF pattern)

128 Russian Settlers Dress: This dress is perfect for pregnancy and nursing. The dress is great maternity wear and the pattern has an option for creating it for easy nursing access post-partum. (128 Russian Settlers Dress PDF version)

This customer made the 128 Russian Settler's Dress for post-partum nursing, but said she wished she'd also made it for her pregnancy.

This customer made the 128 Russian Settler's Dress for post-partum nursing, but said she wished she'd also made it for her pregnancy.

We loved this linen viscose 129 Russian Settler's Dress that a customer made for her pregnancy.

142 Old Mexico Dress: An easy dress to get on and off with plenty of room for a growing belly. Probably best for earlier months of pregnancy. The shirt would be good for nursing as it has room and is short and easy to pull up to nurse. (142 Old Mexico Dress PDF version)

151 Japanese Hakama and Kataginu: I would not have thought of this outfit as maternity wear, but someone in our Facebook Group made the Hakama (pants) and said, with the kimono, it was the most comfortable maternity clothes they wore the whole pregnancy - worn with her 113 Japanese Kimono below. (151 Japanese Hakama and Kataginu PDF pattern)

201 Prairie Dress: This dress is often made as a maternity dress. And the front has an option to make the dress easy to access for nursing babies. (201 Prairie Dress PDF version)

202 Victorian Shirt: Another very roomy and long shirt that has been made for maternity dresses. Very cute! (202 Victorian Shirt PDF version)

270 Metro Middy Blouse: This blouse has a bit of a bell-shape and buttons in front that can make it great for easy-access for nursing. (270 Metro Middy Blouse PDF version)

271 Sunset Wrap: Perfect as a layer to wear to cover up when nursing in public (if you prefer). (271 Sunset Wrap PDF pattern)

May 14, 2022 1 Comment

by Cynthia Anderson

Today I am going to show you how to make the iconic Folkwear 233 Glamour Girl Dress a little more appropriate for summer by shortening the sleeves to make a short-sleeved version. I will show you how to do this with test muslin fabric so you can try it yourself and make the adjustments you might need to get a good fit for a short sleeve.

Dress Details

In the 1930’s and 1940’s movie stars held the American public in thrall and this figure-flattering dress was emulated by many. Movie studios published still photographs of their stars in elegant attire, and fans clamored for the chance to copy the dress, coiffures, and make-up of their favorites. Folkwear’s Glamour Girl Dress is a stunning example of early 1940’s styling, designed to emphasize feminine curves, to drape elegantly, and give the wearer an aura of discreet sexiness.

A close-fitting bodice is highlighted by a narrow “V” neckline. The front bodice and skirt gather into a curved midriff that ties at the center front, providing snug individual fit. A fitted back hip yoke ensures a smooth line. The flared skirt drapes gracefully at center front and back bias seams. And, the three-quarter length sleeves are distinctively gathered at the elbow. The dress zips at left side seam for ease getting in and out. And, of course shoulder pads are essential for the proper fit of the early 1940’s silhouette; but feel free to leave them out as desired.

Three skirt lengths are offered in this sewing pattern: the ankle length of our original evening gown, a 1940’s daytime length, and a strictly contemporary mid-calf length.

Note the reasonable yardage requirements, which reflect the need to conserve fabric during the Second World War. And read more about the history of fashion during that time on our blog here.

Fabric Choices for Warm Weather

This dress has a lovely drape you will want to keep. Any light to medium weight fabric with drape will do. Silk or rayon crepe, satin, challis, or soft cotton make beautiful choices. To make this dress a go-to in your summer wardrobe, use cotton lawn, bamboo, silk/cotton blend, or linen. Choose a fabric that is soft enough to allow for the subtle built-in shaping at the neckline. Be sure to have a look at Folkwear's fabric selection.

Make a Test Muslin

It is best to test any sewing pattern adjustments by making a cotton muslin first. I am going to show you how to transform this glamorous dress into an breezy summer version, by shortening, and slightly widening, the sleeves in a test muslin.

If you are making this dress for the first time, I recommend making a test of the entire dress to ensure a good fit and length. If you only want to test this short-sleeve adjustment, you can just make a muslin of the bodice and sleeves. For this short-sleeve adjustment, you will make the dress as instructed in the pattern, but with the new sleeves.

Design a Short Sleeve for the Dress

Note: Shortening the sleeves will eliminate the gathering detail on the lower portion of the sleeve. The gather is a great feature, but doesn't work for short sleeves. But, the short sleeves will keep you cooler in warm weather.

Sleeve fit is different for everyone and varies depending on the pattern used. How you prefer to wear your sleeves is personal preference and totally up to you. If the sleeve looks or feels too tight or is not as comfortable as you would like in your test muslin, then an adjustment is in order.

A good sleeve fit requires an adequate amount of fabric to go around the arm, plus a little bit more. This extra amount of fabric is called ease. All commercial sewing patterns are designed with some kind of ease.

It generally takes one to three inches of ease for a woven sleeve to fit comfortably at the bicep and allow for a full range of motion, but this can depend on your size and the cut of the sleeve. If a sleeve feels too narrow there is not an adequate amount of ease. Adding 2"(5cm)-3'(8cm) will create more width and room. It does not take a large amount of ease to make a big difference in how a garment fits and feels. Making a simple sleeve width adjustment is not hard to do.

If you are happy with the fit, amount of comfort, and look of a sleeve pattern as is, then leave well enough alone. Go with the sleeve from the sewing pattern straight out of the package.

Sleeve Fit: For the short sleeve in this pattern, you probably want a little more room at the bicep than the fitted long sleeve for comfort and ease of movement. To figure out if the sleeve in this Glamour Girl Dress pattern is roomy enough, start by measuring the circumference of your arm at the bicep (usually the widest part of your upper arm). Take the measurement with your bicep flexed.

Compare your bicep measurement to the sleeve pattern at the upper sleeve or bicep point, as the case may be. Your arm circumference measurement should be at least 2-3 inches less than the pattern measurement. If you feel a little more room may be needed at the bicep, I will show you how to add the ease needed below.

Sleeve Length: To create a new short sleeve for this dress, trace the sleeve pattern for your size using Swedish tracing paper (or any paper that is transparent enough to see through) using the shorten/lengthen line as the cut line for the bottom sleeve edge. You can always make it a bit shorter, but don't forget the hem. I recommend a 1" (2.5cm) hem; 1/2" (13mm) turned up twice. If you decide to shorten your sleeve further, indicate the final length with a horizontal line. The hem will be added when the ease adjustment is made.

Now that you have the length of your sleeve, cut out the sleeve pattern and pin it to the test fabric (on grain for testing). I prefer to cut the sleeve pattern out without the hem added. I find it easier to make the ease adjustments and add the hem on the test muslin. This method preserves your original sleeve pattern, so it does not need to be recreated if you make a mistake or decide to readjust the ease.

Note: This is not a full sleeve adjustment. Which means the armhole and the sleeve seam are not disturbed or altered. This adjustment is made by adding width to the bottom of the sleeve edge only. Then a line is drawn to connect and grade the underarm edge to the bottom of the sleeve. This creates a gradual width increase down the length of the sleeve, ending at the bottom edge. We are widening the sleeve to create a short sleeve because the cut and fit of the Glamour Girl Dress's sleeve is fairly narrow.

Adding Ease

The sleeve for your pattern size may still need more ease added to make it fit well. Even though the sleeve pattern was designed with ease built-in, adding a bit more can make for a more custom fit.

To widen this sleeve, extra width (ease) needs to be added. The amount of ease listed for the sizes below should be considered a maximum. This adjustment is meant to make a narrow sleeve design a little bit wider for comfort. For a basic rule of thumb, you can use the numbers below for your size to add some extra room (ease) to the bottom of a short-sleeve for this Glamour Girl Dress. You can, of course, add a little more or a little less, depending on how you prefer the sleeve to fit.

Making the Adjustment

With the sleeve pattern pinned to the test fabric, draw a horizontal line that extends beyond each side of the bottom sleeve edge.

Divide the amount of ease you are adding in half and add this half-measurement to each sleeve edge on the drawn horizontal line, as seen below.

In this case, I am making a size medium and adding 2" (5cm) of ease. The 2"(5cm) of ease is divided in half, adding 1"(3cm) to each side of the sleeve edge. Remember that the seam allowance has already been added to the pattern and you do not need to add more.

Using a French curve or hip curve draw a smooth line connecting the under sleeve edge to the newly added width. The connecting line can have a slight curve or be more straight.

Using a hip curve will allow you to experiment with the degree of curve the line has. More ease can be gained through out the sleeve edge if there is less curve to the line drawn.

Draw the same curved edge on the opposite sleeve edge.

Draw a perpendicular line at the newly widened edge. Extend the line down to accommodate the hem to be added.

Determine the total hem depth and divide it in half. In this case, I am adding a 1" (2.5cm) hem. Draw a horizontal line parallel from the bottom edge of the sleeve that measures half the hem depth, 1/2-inch (13mm) in this case.

Stitch up the sleeve right sides together as normal and add the sleeve to the armhole according to the pattern instructions. And if you want, shorten the skirt hem for cool comfort!

For a bit more fun, also consider changing up the curved midriff and back yoke. These details are perfect for playing with pattern design direction or cutting on the bias. Try these options on a test muslin to see what you like.

The Folkwear 233 Glamour Girl Dress paper pattern and pdf is on sale the month of May. Not only is it a great pattern for summer, but it is always nice to get ahead in next season's sewing. You will not regret the adding the long sleeved version of this dress to your upcoming Fall/Winter wardrobe!

Hope you enjoy making and wearing this shorter sleeve version of the Folkwear 233 Glamour Girl Dress! As always, share what you make!!

May 12, 2022

by Molly Hamilton

We recently resized and re-released the 121 Guatemalan Gabacha. This cute dress (or apron) pattern was first published by Folkwear in 1978, and was based on dresses and aprons that were commonly found in markets near the town of Chantal where a large textile mill in the 1960s and 70s produced gingham, and Western influences met with Guatemalan textile brilliancy to come up with this apron (and dress).

The Gabacha is fairly simple to sew, but there are a few details that can make creating the sleeves a little easier, especially if you are making the shaped cuff. The shaped cuff really quite simple and fun and adds a great detail to the dress, so don't be intimidated by it. For a tip on making the bias ruffle, go here.

Seams

I made my dress from a cotton lawn and I wanted to use French seams to finish all my seams because I like the look and feel of French seams in a garment with lightweight cotton. This works fine for this dress, except for where the dress attaches to the yoke and the ruffle to the dress; there you will either need to finish the raw edge that is folded under, or just leave it (it is basically covered by the gathered edge anyway). The French seams work fine for the underarm gusset and for the set-in sleeve.

Sleeve Pleats

The easiest way to create the sleeve pleats on the sleeve cap is to clip into the seam allowance by 1/4" or less at the pleat marks. This allows the pleat to be easily and accurately folded toward the dot (pleats fold toward the front of the sleeve - make sure you are making a left and right sleeve correctly, especially if your fabric looks the same on the right and wrong sides). Machine baste the pleats in place.

Sleeve Gusset

This dress has a underarm gusset that helps the sleeve attach to the dress body. This is an old-fashioned (or traditional) technique used to provide room in the arm for garments that are made with straight edges (i.e. no curved armsyce). Gussets are not hard to sew, but you do need to be precise. This particular gusset is one of the easiest I've ever sewn because you don't need quite so much precision because you are only attaching it on three sides and therefore there are less seams to match.

To attach the gusset, place it on the sleeve (I did French seams, so wrong sides together first) matching the dots. Be sure the wide edge of the gusset is on the pleated side of the sleeve (this wide edge will attach to the dress). Sew one side of the gusset to the sleeve and then sew the other side of the gusset to the sleeve, again matching dots. If you are doing French seams like I did, you will do wrong sides together, then right sides together enclosing the raw edge. Your seam line will go through the dots. Often for gussets, you only stitch between the dots, but it is fine to stitch through the dots on this gusset.

Be sure to match dots when sewing gussets.

Be sure to match dots when sewing gussets.

First side of gusset is sewn. Second side will also be a French seam; wrong sides pinned together, I sewed a slight 1/4 (6mm) seam.

First side of gusset is sewn. Second side will also be a French seam; wrong sides pinned together, I sewed a slight 1/4 (6mm) seam.

Gusset with one side finished and the second side being sewn on - wrong sides together and sewn before turning the right sides together to finish the French seam.

Gusset with one side finished and the second side being sewn on - wrong sides together and sewn before turning the right sides together to finish the French seam.

Second side of sleeve gusset, folded right sides together. First seam of gusset is sewn, second seam will be through the dots on the left.

Be sure to attach gusset so that the wider edge of the gusset goes to the side of the sleeve with the pleats (this will get sewn to the dress). The V end of the gusset goes toward the cuff of the sleeve.

Shaped Cuff

I love the shaped cuff on this dress. It is subtle but a tailored design that makes the dress special. The straight cuff is very simple and you will follow the same instructions as I did here without turning under the shaped edge.

First, you need to turn under 1/2" (13mm) on the shaped edge (or if using the straight cuff, turn under 1/2" on one edge). It helps a lot to mark the 1/2" seam line. I measured down 1/2" from each valley and peak of the cuff and then connected the dots. I then clipped to the dot at each valley so that I could turn down the seam allowance. At the peaks, I folded the fabric edges over each other to make the corner. The draw-in seam line helps make this precise and give a nice, even shape to the cuff. Note: I often use Crayola ultra washable thin markers to mark fabric when I sew. They come in a range of colors that work on just about everything (but black), and they wash away easily.

Once the cuff is "shaped", sew the seams together at short ends and press open.

The shaped cuff with edges turned under, ready to be sewn to the sleeve.

Attaching Cuff to Sleeve

Sewn two lines of gathering stitches to the cuff edge of the sleeve and pull up stitches to gather evenly.

Gathering lines pulled up on sleeve edge, ready for cuff to be attached.

Gathering lines pulled up on sleeve edge, ready for cuff to be attached.

To attach the cuff to the sleeve, you will need to place the right side of the cuff to the wrong side of the sleeve, matching raw edges, and matching the cuff seam line with the gusset point.

Right side of cuff facing wrong side of sleeve; raw edges together (the shaped edge is away from the gathered edge of sleeve).

Right side of cuff facing wrong side of sleeve; raw edges together (the shaped edge is away from the gathered edge of sleeve).

Adjust the sleeve gathers to fit the cuff and pin in place. Sew the cuff to the sleeve at the 1/2" (13mm) seam line. You can trim the seam to about 1/4" (6mm) if desired to reduce bulk. Then turn the cuff out and press the seam allowance toward the cuff.

Now, turn the cuff back toward the sleeve at the fold line. The shaped cuff edge will cover the seam line of the cuff/sleeve. Adjust and pin cuff in place. I placed pins at each valley and peak of the cuff. You should topstitch the shaped cuff to the sleeve being careful to stitch close to the edge of the folds of the shaped cuff. This is also where having the marks on the shaped part of the cuff can be helpful for stitching. Pivot at each corner of the shaped cuff leaving the needle down in the fabric. If you are getting near a corner but feel your stitch might go over or be too short, you can adjust the stitch length for one or two stitches to get it to the peak (or valley) of the corner to be more precise with your topstitching.

Once the cuff is stitched down, you can remove the gathering stitches at the cuff and sew your sleeve onto the dress. Again, match dots and notches, and you should have no problems. I used a French seam here and so sewed the first seam with the wrong sides together and a slight 1/4" (6mm) seam allowance, I trimmed the seam allowance slightly to be even and sewed the seam again at the seam line with right side of sleeve facing right side of dress.

This sleeve is fun and a great detail of this dress. I hope this tutorial helps you get a clear understanding of putting the sleeve and shaped cuff together for our 121 Guatemalan Gabacha. For a video to see how to do these steps, check out the link below!

Happy sewing!

May 09, 2022 1 Comment

WWII was THE dominate force in the world in the first half of the 1940’s and fashion was profoundly influenced by its impact. Every aspect of life and the resources required to support the war effort demanded sacrifices that would unite the population. The need for uniforms took precedence and shifted manufacturing away from everyday clothing for men, women, and children. Civilian clothing styles were dictated by rationing and utility which would continue even after the war had ended. America, the United Kingdom, and France were all drawn into WWII. Yet the impact of the war would prove to effect each nation differently. All three nations would come away with a different story told through the everyday lens of fashion. Wartime did not mean giving up on beauty and dressing the best you could. However, it did mean new considerations and a sense of cooperation was be needed to ultimately win WWII.

Despite the restrictions and difficulties of war, women, especially in the US and Britain, were encouraged to fulfill their patriotic duty to look attractive. The US and British governments with the help of designers would help mold the look. In America, Hollywood movie stars would model these designs enticing women to emulate and escape through the clothing on the movie screen.

Folkwear’s 233 Glamour Girl Dress and the 247 Lindy Dress each met the parameters set by wartime restrictions, while still providing women with a touch of glamour and daily utility to their wardrobes. Dresses like the 247 Lindy Dress (and our out-of-print 235 Sporty Forties' Dress) became a unifying everyday uniform, allowing women to go about their lives with the ease of knowing they looked good without fuss. It was part of the new "utility" look. While The 233 Glamour Dress and it sensual lines provided a much-needed escape and a bit of glamorous fun. Keep reading to learn how fighting Hitler's war was fueled by fashion and weaponized by glamour.

By the start of the war in 1939, Paris had long enjoyed its status as the undisputed capital of fashion and culture, leaving the world transfixed. Fashion magazines, news publications, and going to the movies were portals to all things French. However, six months into the war on June 14, 1940, a four year German occupation would seal Paris and all of France off from the gaze of its captivated audience. French life and fashion design did not end, but many talented designers and creatives would shutter their studios, flee, or join the fight. The artists and designers that remained continued to create the best they could despite the occupation. This closed bubble resulted in fashion and art that would diverge vastly from the world outside of France.

Hitler coveted Paris and considered it a jewel to be taken. The Vichy government of France handed Paris over to Hitler in part to keep it from being destroyed, preserving its beauty and talents. The President of the Chambre Syndical de la Haute Couture, Lucien Lelong, convinced the Nazis that the fashion industry should be kept alive to preserve jobs and keep French talent from being relegated to dangerous work for the Germans. Implying that French talent would be part of Hitler's spoils. Paris fashion houses continued to produce two fashion collections a year, dressing mostly the wives of Nazi officers and privileged women from countries that sided with Germany. The occupation would prove to be a safety net of sorts, allowing much of French life to continue uninterrupted. However, the average French woman was left to dress in rags and make do with much resentment.

Prior to the war, American designers merely copied Paris fashion and the British followed suit. With France cut off from the world, the US and UK would have to find their own muses. Rationing of resources would steer fashion in both nations, setting the challenge of producing appealing clothing within government issued restraints. Both raw materials and labor were allocated to the war effort, leaving civilian clothing in short supply and women at the forefront of producing and organizing what was needed. Limited availability of fabric lead to tightened bodices, shortened skirts, and dispensing with extra details, such as pockets, cuffs, large pleats, and linings. Items consisting of metal, like buttons, clasps, zippers, were limited in civilian garments. Supplies of manmade fibers such as nylon were increased for civilian clothing, leaving more durable and warm fabrics like wool for uniforms, silk for making parachutes, and dyes for making explosives. Manufacturers of shoes were committed to supplying the troops with boots, resulting in a civilian shoe shortage. Church and society women's charities organized Tag and Jumble Sales to help ease the clothing and shoe shortages that continued even after the war ended. Utilitarian and uniform-like clothing became a sacrificial badge in everyone's fight for victory.

James Laver in Costume and Fashion: A Concise History writes, “The look was simple but stylish, with good proportion and line. It incorporated padded shoulders, nipped-in waist, and hems to just below the knee.” The Utility dress was born. Rations of fabric would persist even after the war and the Utility dress would be reinvented as the shirtwaist dress (similar to our 247 Lindy Dress), to lessen the reference to war.

Women on both sides of the Atlantic were encouraged to "Make-Do and Mend," which was a continuing trend born out of the Great Depression. Classes were held and an extensive range of how-to booklets were provided to women and children that taught useful skills on how to extend the life of the families' clothing. These classes provided not just needed skills, but a social outlet as well. Using outdated clothing to make new, more fashionable designs was encouraged. This creative outlet proved to be a much needed diversion for women and girls of all ages.

After the experience of Europe's Great War (WWI), the importance of women’s roles in supporting the war effort had been cemented and there was no doubt of the role moral played in seeing people though the sacrifices required of every individual. The British people were still recovering from the destruction and loss suffered with WWI and the government took strong action to rally the population once again. In order to encourage women to embrace and shift away from popular feminine detailing that had reigned in the 1930's, a scheme was devised by the British government. The prestigious designers Norman Hartnell, Hardy Amies, and Edward Molyneux of The Incorporated Society of London Fashion Designers or Inc. Soc., all submitted designs to help promote the cause. Their efforts changed what women would consider fashionable. Women made the most of the simple yet sophisticated look and its dignified allure.

Out of this collaborative effort came a fashionable boxy suit, with a rounded-edge collar and lapels, and a flared below the knee-length skirt. Previously popular Tweeds and plaids translated nicely into Utility clothing. Women were excited to see familiar fabrics take on a modern look. Bright colors, prints, and patterns helped elevate the simplicity of the designs. Not only were these designs economic and resourceful, but they were also easy to sew, making them accessible to everyone.

While rationing and purchasing for everyday needs with coupons was a reality for both American and UK households, rationing for clothing was not as severe in the US. As a result a new energy emerged that inspired American designers and the public to embrace a sense of optimism.

With the absence of French influences, American designers thrived in their freedom to define a new American look. This clean slate set the stage for ready-to-wear American sportswear. The clothing introduced was simple and easy to wear. The active spirit of the fashions proved trendy and popular, setting the stage for what would eventually become the iconic Sporty American look (see Folkwear's 235 Sporty Forties dress, which is coming back into print later this summer!).

Norman Norell and Claire McCardell were two American designers that filled the gap for high-quality designs that previously had come from Europe. Norell added glamour and sparkle to the bleak days of the war, by covering the simple Utility dress in sequins that were abundant and ration-free.

McCardell introduced an even more sporty design aesthetic that appealed to the desires and modern attitudes of women. The casual practicality, and comfort of her designs, worked around rationing restrictions with ease, producing designs that would become American classics. McCardell replaced scarce wool and silk with, denim, seersucker, and jersey to make classic dresses and separates. McCardell’s wrap dress was first introduced in denim and came with a practical oven mitt to match! The wrap dress enjoyed a longevity that lasted well into 1950’s. The classic wrap dress was born and McCardell included it in her collections for the rest of her career.

.

The US and British governments adopted similar strategies to encourage support for the war, while still maintaining morale. The US government and cosmetic companies partnered to propagandized beauty.

Playing off Hitler's hate for "made-up women" cosmetic companies were quick to create campaigns that encourage women to wear make-up responsibly, but not neglect beauty. Lipstick was weaponized. In the US and Britain, women were encouraged to wear red lipstick as warpaint. In 1940, Elizabeth Arden created a lipstick to perfectly match the red piping on women's military uniforms. Official military kits for women included matching lipstick, cream blush, and nail polish. Besides sticking it to Hitler, wearing lipstick became a symbol of a free society worth fighting for. Wearing make-up became a coping mechanism, that helped women to maintain a sense of dignity and pride, during a time of fear and uncertainty. Lipstick is still considered a pick-me-up for everyday life.

Prior to the war any self-respecting women would have never left the house without stockings. Silk stockings were a mainstay in every woman's wardrobe, but they did not stretch, were delicate and ripped easily. Plus, the support of a garter belt was needed to hold them up.

By the 1930's the US was importing the lion's share of the world's silk supply (mostly from Japan) for the sole purpose of making hosiery. The E.I. DuPont de Nemours and Company hired a scientist by the name of Wallace H. Carothers, who invented Fiber 6-6 or what would become Nylon. Dupont was quick to recognize the economic impact of making hosiery out of nylon and within three hours of the experimental debut, 4000 pairs would be sold. Dupont would gain 30 percent of the hosiery market almost overnight. Women also recognized the economics of nylon stockings and were happy to abandon silk.

WWII redirect the use of nylon hosiery and how women would cope. Once the US was attacked by Japan, the demand for a strong material (nylon) was needed for manufacturing glider tow ropes, aircraft fuel tanks, flak jackets, shoelaces, mosquito netting, hammocks, and parachutes. Women's hosiery would have to take a back seat to the war effort.

Due to the shortening of skirt lengths, and the redistribution of nylon to the war effort, women were left with the issue of bare legs. Women had fallen in love with nylon stockings and were not keen on going back to silk. Besides, used silk stockings were being collected for making parachutes. So, women did the next best thing. They shaved their legs and drew a liquid paint line up the back of their legs to emulate the seam line of hosiery. This gave the cosmetic industry yet another product to exploit during the war. By 1942, nylon stockings hit the black market, but shaving remained.

As mentioned previously, Hollywood would do much to propel the fashion and cosmetic industry to thrive while inspiring women to do the same. Even if rationing limited availability, women were motivated to do the best they could with what they had. Glamorous movie stars like Katherine Hepburn and Ingrid Bergman were the epitome of women with strong yet feminine allure. Women wanted to be like them, and men were intrigued.

During the war, the US and Britain had become leaders in fashion and they were eager to continue their fashion status after the war ended. However, a liberated Paris was poised to reclaim it’s standing.

Even though the war officially ended in 1945, it would take time for the world to regain a sense of normalcy. Britain would struggle to recover from the extreme devastation it suffered for a decade or more. It took years to rebuild and for supply chains to recover and innovate once again. Rationing of clothing would not end until 1949. The US recovered more quickly, simply because the war had not touched its shores and manufacturing would resume. Fabric shortages would continue in the US and the UK until demand could be met once again. With peace came the desire to put the war behind and to move forward with new possibilities. As a result women lost interest in the wartime Utility dress, uniforms were stuffed in the backs of closets, and the world impatiently waited for something new.

Christian Dior and his “New Look” would not only reinstate Paris to the world’s fashion pedestal. But his exaggerated feminine silhouette consisting of a tight fitted bodice, tiny cinched waist, voluminous long skirt gave women the elegant and prosperous look they longed for. It was not just a new look, it was a transformative phenomenon.

May 01, 2022

We are excited to offer this very cute sewing pattern back in print and in larger sizes (and as a PDF pattern)! The 121 Guatemalan Gabacha is a dress or apron that has a few special details. There is handwork detailing that we will show soon, but also several pieces of the pattern can be cut on the bias.

The bias detailing on the 121 Guatemalan Gabacha is a simple, but fun way to add a little interest, especially if you are using striped or checked fabrics. Ginghams are great for this pattern with the bias detailing. You can add as little or as much bias detailing as you want. For all the bias options, you can cut the pockets, yokes, front, inset, and ruffle on the bias. Or you may want to just do the pockets, or just the front yoke inset. Cutting all these pieces on the bias does use more fabric, so check yardages if you are interested in this option. Of course, cutting just the pockets on the bias (or the front inset) won't really add any more fabric. Just be judicious when laying out your pattern.

When I made this yellow dress, I wanted to add nearly all the bias detailing. I cut the pockets, front inset, and ruffles on the bias. I had about 4 yards of this 44" plaid lawn and it was more than enough to get all the bias cuts. Because these pattern pieces are smaller and not full garment pieces, you don't have to worry so much about stretching. Just handle gingerly. For lots of bias sewing tips and tricks, see our blog post here. The ruffle is the largest piece and may give a little trouble feeding through some machine for gathering, but I had no problems with it at all.

When adding bias detailing like this there is very little you do differently than if the fabric was cut on the grain. But the biggest change in the way you sew the garment together is in the ruffle. The bias ruffle is cut with a 45 degree angle on the short ends. If you sew the ruffle pieces together as you would a typical on-grain pattern piece, the ruffle will not work. Normally, you put two pieces of the fabric with right sides together, matching any notches, and sew along the seam line. If you do that here (see below for example), you end up with your ruffle pieces facing each other at 90 degree angles.

Right sides together, matching edges = WRONG WAY TO SEW RUFFLE TOGETHER

Right sides together, matching edges = WRONG WAY TO SEW RUFFLE TOGETHER

You'll end up with a ruffle at a 90 degree angle to the other ruffle

CORRECT WAY TO SEW THE RUFFLE

With right sides together, place the ruffle at 90 degree angle to the other ruffle and match raw edges. Sew on seamline from one end of the angle to the other. There are notches to help you at the 1/2 inch seamline here. You want to match the seamlines to each other, not really the raw edges. So you will have little "ears" sticking out from each end of the seamline. When the ruffle is folded out, these "ears" can be trimmed, but you will have ruffle top and bottom edges that match each other.

Here's a short video of the same thing!

April 30, 2022

Our Old Mexico Dress is a favorite and part of that lure is the embroidery that can be added to the dress. We are happy to invite you to join Sarah Pedlow at Threadwritten for another on-line embroidery class focusing on the skills and techniques used in for this dress. This next class takes place May 14, 2022 and registration is open now.

This pattern also makes a really useful shirt, shown here in a mix of machine-embroidered fabrics. Note the way the shoulders are constructed, this allows for a wonderful mix of fabrics on this pattern.

Learn more about the Threadwritten embroidery class on May 14, 2022 here.

Find the PDF version of the pattern here.

Find the Print version of the pattern here.

April 13, 2022 3 Comments

by Esi Hutchinson

Happy spring to you all! When I found out we were featuring the 266 Greek Island Dress sewing pattern for April, I volunteered to make a sample I would wear myself. The Dress is a great slip dress that I wanted to personalize for my style. I loved the style of the Jacket as well, especially the collar that adds a dashing element to the outfit. So I am going to show you how I personalized the dress, as well as a couple of pattern and sewing tips and tricks while I created this outfit.

This pattern is quite formal, however if you want to make it more casual you can change up the fabric as well as what you choose to style these clothing items with. See the end of this blog for several ways I plan to style the Dress and Jacket. I did not want to make the Tunic because, while absolutely gorgeous, it was a little formal for my sense of style. You can see the line drawings of all the garments in this pattern below.

We suggest silk, crepe de chine, charmeuse, polyester to make any of the garments in this pattern. They are really great made out of lightweight (or medium weight) fabrics with good drape. We have some beautiful Tencel twill fabrics in stock that will suit the anything in this pattern. The Aqua and the Mulberry are my personal favorites.

I really wanted a white dress so I chose a rayon lyocell blend that I found, and a lilac cotton voile for a lightweight jacket.

I was inspired by Cynthia's blog making the 213 Child's Prairie Dress and Pinafore. It's the cutest pinafore I have ever seen with the most lovely machine-stitched embroidery of wildflowers. You can find this embroidery pattern here in our shop. When I found out I was going to make the 266 Dress a light bulb turned on in my head and I thought that is was a great way for me to embellish this dress.

Making the Dress

I tried on one of Folkwear's samples of the 266 Dress and decided I wanted to alter it by bringing in the waist on the front and back by one inch so it would be a bit more fitted at my waist. I would not bring this dress in any more than an inch. The dress is naturally loose-fitting and bringing it in further could alter the drape in a less than flattering way. However if you know how to do it - go for it, but make a muslin first.

My waist line matched with the notch on the side seam. I made a mark 1" from the side seam at the waist notch. Then, I drew a line from 1/2" (13mm) below the top of the side seam to the 1"(2.5cm) mark. And from the 1" mark to about 5 inches below the waist mark. I used a French curve to create a gently curved line connecting those points. I drew in a new notch at this new waistline. I did the same thing for the back piece. I also shortened the dress to just below knee length. This is easy to do at the lengthen/shorten lines on the pattern.

I cut out all my fabric pieces using a white rayon lyocell blend and cut a lining with the same fabric because it is semi-transparent. I could have used a darker fabric, but I needed white drapey fabric for my vision for this dress. And white fabric with drape is often somewhat see-through. I just cut another layer of the dress portion.

It is easier to embroider the dress in separate pieces in my opinion. So I embroidered the dress before sewing it together. You can read more about that process in Cynthia's blog or in the wildflower embroidery pattern.

I transferred the embroidery design template to my dress using a washable marker, I have mentioned before in other blogs that Crayola markers are great except they are quite pigmented and it will be hard to see your progress if using the for this kind of work. You could also use a piece of transfer paper or non-permanent pen in a color that is visible and made especially for transferring a design to fabric. This blog is a great resource. Do not iron the embroidery with the non-permanent pen or marker. Wash it first, then press.

I made sure to start my design an inch and a half above the bottom raw edge, keeping in mind that I will stitch the design slightly below the hem line. I did this so that when I folded hem, the very bottom of the design will fold under and there will be no gaps between the bottom of the dress and the embroidery.

Front of Dress, transferring the embroidery design

I started machine stitching the design beginning with different shades of green on the stems and stalks. I suggest when using delicate fabrics use a longer stitch as there will be less tugging and bunching of the fabric. Stabilizer would also be helpful for some fabrics. Cynthia also mentions in her blog to double up your thread in the top needle as this can create more dimension to your embroidery as well as using different shades of a color. You can keep the bobbin thread the same color throughout the embroidering process. I used white in my bobbin the whole time to match the dress color.

Doubled up thread in the top needle

Doubled up thread in the top needle

Stems stitched.

Stems stitched.  Starting on the flower heads.

Starting on the flower heads.

I decided to add a little bit of embroidery on the front yoke to tie the look together.

Dress and lining sewn together and ready to be put together.

Dress and lining sewn together and ready to be put together.